Our Story

In 2014, our sister company MES created an internal tool to streamline the entire RFQ process from creating and sending RFQs to receiving, comparing, and awarding RFQs all in one, centralized system. About 2 years later in 2016, MES created another tool to help centralize product development and the APQP process, an automotive industry standard.

Keep in mind – before this, MES had all of the estimators, sales, and sourcing engineers who would have to spend hours translating quotes, and comparing cost breakdowns and despite their best efforts, it was prone to errors since suppliers would be quoting in excel/PDF and often change the templates that they submitted in. After that, estimators would then use another template to create a piece price + margin to arrive at a landed cost which includes SG&A, profits, taxes/duties, etc. This was a VERY tedious and manual process prior.

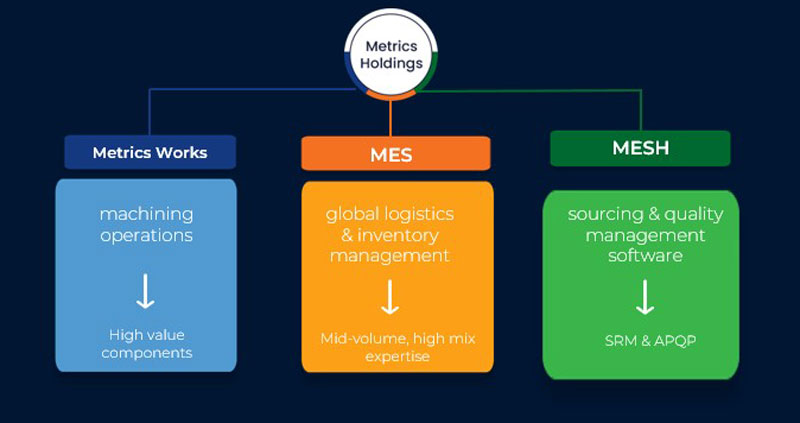

In 2020, MESH was founded with one sole purpose: to optimize sourcing & quality processes for manufacturers. While there are numerous RFP/RFQ tools out on the market, there was a major gap in the offerings for manufacturers who deal with custom-engineered components that include large 3D drawings, documents, and files. This small to mid-size manufacturing sector was majorly underserved and we hope to fill that gap as much as possible.

MESH has a suite of products that can assist customers from strategic sourcing to digital procurement and supplier management. Additionally, the MESH QMS allows engineering and quality teams to manage APQP/quality projects as well as have field reporting from warehouses, supplier factories, inspection centers, etc.